Early flight jackets were made of ordinary nylon fabric. When the plane caught fire, the flames would melt the flight jacket and stick it to the pilot’s body. In the 1960s, DuPont invented aramid 1313, which is NOMEX flame retardant fiber, also called meta-aramid.

, detailed introduction:

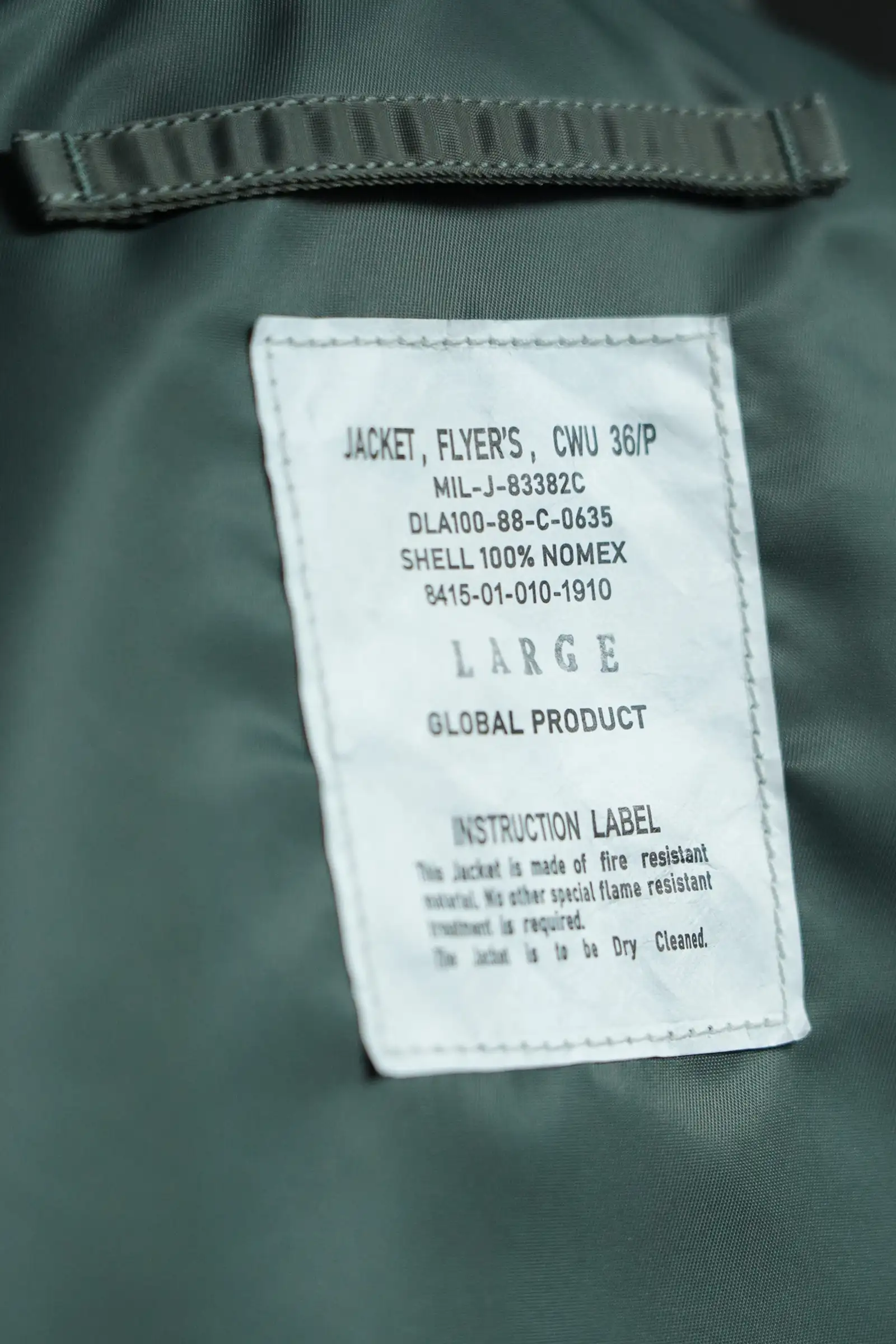

Until the 1970s, there were several major breakthroughs in the development of fire-resistant fabrics for flight suits or flight suits. These led to changes in the clothing equipped by pilots at that time. Eventually the CWU-45/P and its close relative CWU-36/P were developed. When the old MA-1 made of nylon catches fire, the material of the shirt tends to melt on the wearer’s body due to heat. The above problems have been improved in the new flight suit. The CWU-17/P developed around 1973 was the prototype of the 36/P and 45/P. In 1977, the jacket was renamed CWU-45/P [Military Project MIL-J-83388A], and the removable pockets inherited from CWU-17/P [Military Project MIL-J-83388D] were Shrunk. In 1980, the collar edge narrowed. Next, the rear live pleats are narrowed [Military Project MIL-J-83388C]. In 1984, the collar stitching was simplified [Military Project MIL-J-83388D]. Therefore, from the changes in these military items, we can trace the production period of these coats. At present, air force pilots are equipped with lighter 36/P or 45/P for use in warm climates and colder weather respectively. From a distance, the two coats look exactly the same, but they use different materials for the lining.

Author: Shabaitian

Link: https://www.zhihu.com/question/263484303/answer/497879038

Source: Zhihu

Copyright belongs to the author. For commercial reprinting, please contact the author for authorization. For non-commercial reprinting, please indicate the source.

NOMEX has excellent heat resistance (note that it is “fire-resistant” and not “anti-fire”). Although it is a chemical fiber product, it can withstand temperatures of 3 cm from an open flame at 300-400 degrees Celsius. , it can last for 10 seconds without being ignited; it can be used continuously for 100 hours at 260 degrees Celsius and still maintains 70% of its original strength. And forms a thermal insulation layer between the human body and the heat source. Not only that, it is also resistant to strong acids and alkalis, is not sensitive to moisture, has good insulation, is also very soft, durable and breathable. In addition to military fire-resistant suits, racing drivers’ underwear, masks, socks, and gloves are also made by NOMEX. This material is also the material used to make flame-retardant hoods on British and American warships.

So in 1972, the US military commissioned Alpha and other contractors to make new flight jackets using NOMEX, resulting in the CWU-36/P jacket.

The fabric has elastic cuffs and waist, and the sleeves are very long to accommodate pilots who sit for long periods of time with their arms stretched forward or raised.

There is a small pocket on the left and right arms, which can hold pens, cigarette lighters and other common sundries for pilots.

The positioning is different from that of a leather flight jacket.

Two are flame retardant materials:

Early flight jackets were made of ordinary nylon fabric. When the plane caught fire, the flames would melt the flight jacket and stick it to the pilot’s body. In the 1960s, DuPont invented aramid 1313, which is NOMEX flame retardant fiber, also called meta-aramid.

.

In the early 1950s, the U.S. military successively launched L2, L2A, L2B and other models of flight jackets. L2B was the designated clothing for workers working in medium and low temperature areas. It replaces the L-2A flight jacket, which was made exclusively from Air Force blue nylon fabric. When the driver is exposed to low temperatures in an open cockpit, the two can replace leather jackets to a certain extent to keep out the cold. Nylon material makes movement more convenient.

The L2B military-spec flight jacket experienced a decade of great development in the aviation industry in the 1960s. It was not until the 1970s that the L-2B was replaced by the CWU 36/P jacket, but was worn by some ground crew and US Air Force personnel into the 1990s. The main difference in design from MA-1 is the epaulettes. The biggest difference is that the MA-1 was originally a bomber flight suit. Bombers need warmth and waterproofing for ultra-high altitude operations, while the L2-B is used in medium and low temperature environments without adding a thermal layer.

Until the 1970s, there were several major breakthroughs in the development of fire-resistant fabrics for flight suits or flight suits. These led to changes in the clothing equipped by pilots at that time. Eventually the CWU-45/P and its close relative CWU-36/P were developed. When the old MA-1 made of nylon catches fire, the material of the shirt tends to melt on the wearer’s body due to heat. The above problems have been improved in the new flight suit. The CWU-17/P developed around 1973 was the prototype of the 36/P and 45/P. In 1977, the jacket was renamed CWU-45/P [Military Project MIL-J-83388A], and the removable pockets inherited from CWU-17/P [Military Project MIL-J-83388D] were Shrunk. In 1980, the collar edge narrowed. Next, the rear live pleats are narrowed [Military Project MIL-J-83388C]. In 1984, the collar stitching was simplified [Military Project MIL-J-83388D]. Therefore, from the changes in these military items, we can trace the production period of these coats. At present, air force pilots are equipped with lighter 36/P or 45/P for use in warm climates and colder weather respectively. From a distance, the two coats look exactly the same, but they use different materials for the lining.

··········································

The predecessor of the 36/P flight suit was L2/b. The CWU-17/P developed in about 1973 was the prototype of 36/P and 45/P. After continuous improvement, the 36/P was completed in 1984 and has been improved to this day.

The 36/P flight jacket, like other flight jackets, adopts a higher waist design and looks “short and fatter”. This is to adapt to the situation when pilots are in full flight gear, avoid various equipment on the waist, and wrap the lower body with a life vest, Flying saddle straps and various flying equipment.

In addition, there are CWU-45/P flight jackets with thicker thermal insulation cotton, which are worn by pilots outside the CWU-27/P one-piece flight suit to protect against cold weather and are common to all military branches.

36/P and 45/P look very similar in appearance. The identifying features are: 45/P has an inner wind flap and a double-line front patch pocket. 36/P is for spring and autumn so there is no wind flap and a large front patch. Bag single seam shown is different from 45/p

The commercial version 36/P material is non-flame retardant, please do not do high temperature testing.

Gray nylon 66 material fabric

The small round lapel design has the characteristics of the 1970s.

Early Blue Angels embroidered performance badge with replaceable Velcro on the back

*

*

The 36P arm bag is similar to the MA1 but not the same. The 36/P arm bag is more three-dimensional and has more space.

The two large slanted opening pockets are convenient for inserting hands at a natural angle, and the pocket mouth has a reflex design to prevent items from falling out.

Hidden zipper design

Reviews

There are no reviews yet.